|

Sino Industrial Group Co.,Ltd

|

steel plate steel coils galvanized steel coils

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

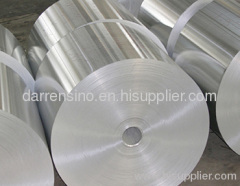

Galvanized steel coils is products which is produced by galvanizing cold rolled steel coils.

Processing Of Galvanized Steel Coils:

Galvanized steel coils is products which is produced by galvanizing cold rolled steel coils. It is the process of coating steel with a thin zinc layer, by passing metal through a molten bath of zinc at a temperature of around 460℃. And galvanized steel coils is wildly used in the applications where rust resistance is needed.

Standard Of Gavanized Steel Coils:

The standard of galvanized steel coils varies according to different countries, but which is major used as per EN,JIS,GB and ASTM.

Steel Grade Of Galvanized Steel Coils:

Standard of galvanized steel coils as per EN 10327, then the steel grade of galvanized steel coils can be DX51D, DX52D,DX53D,DX54D,DX56D,DX57D.

Standard of galvanized steel coils as per GBT2518, then the steel grade of galvanized steel coils can be 01, 02, 03, 04, 05, 06.

Standard of galvanized steel coils as per JIS G3302, then the steel grade of galvanized steel coils can be SGCC, SGCH, SGCD etc..

Standard of galvanized steel coils as per ASTM A653, then the steel grade of galvanized steel coils can be CS, FS, DDS, EDDS, SS etc..

Different steel grade of galvanized steel coils means different drawing quality.

Zinc Spangle Of Galvnaized Steel Coils:

Regular Spangle: The finish produced on hot dipped galvanized steel coil in which there is a visible multifaceted zinc crystal structure.

Minimized Spangle: The finish produced on hot dipped galvanized steel coils in which the grain pattern is visible to the unaided eye, and is typically smaller and less distinct than the pattern visible on regular pattern.

Spangle Free: The finish produced on hot dipped galvanized steel coil in which the visual spangle pattern is not visible to the unaided eye.

Zinc Quality Of Galvanized Steel Coils:

The zinc quality of galvanized steel coils which is available from 30g/m2—275g/m2.

Surface Treatment of Galvanized Steel Coils:

Usually we will do the surface treatment below for the finished galvanized steel coils to enhance the resistance to corrosion during storage and transportation.

C: chemical passivation

O: oiling

CO: chemical passivation and oiling

S: sealed

P: phosphated

PO: phosphated and oiled

Application Of Galvanized Steel Coils:

Galvanized steel coils is used in a very wide range, mainly used in construction, light industry, automobile, farming and commercial fishing industries. Construction industry which is mainly used for manufacture of industrial and civil construction corrosion roof, roof grille. Etc. light industry manufacturing home appliances with its shell, civil chimneys, kitchen appliances, automobile industry, mainly for the manufacture of car parts and other corrosion-resistant. Nongmu Yu oweners do use food storage, frozen meat and aquatic products processing equipment, etc; business is mainly used as strorage and transportation of materials, packaging equipment and so on.

Name | Galvanized Steel Coil | |

Standard | JIS G3302 | SGH/SGC series |

GBT2518 | 01-06 | |

EN 10327 | DX51-54D DX56-57D | |

Material | CR/HR steel coils,acid-washed steel coils | |

Zinc Coating | 60g/m2-275g/m2 | |

Zinc Spangle | Normal/Minimized/Free Spangle | |

Surface Quality | A/B/C | |

Surface Treatment | C/O/CO/P/PO | |

Thickness | 0.18-3.0mm | |

Width | 12mm-1250mm | |

ID | 508mm/610mm | |

Coil Weight | 3-8MT | |

Packing | As Per Client's Requirement | |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Aluzinc Galvanized Steel Coils

Galvanized Steel Coils Sheets

Galvanized Steel Strip Coils

Steel Coils

Galvanised Steel Coils

Coated Steel Coils

More>>

.gif)